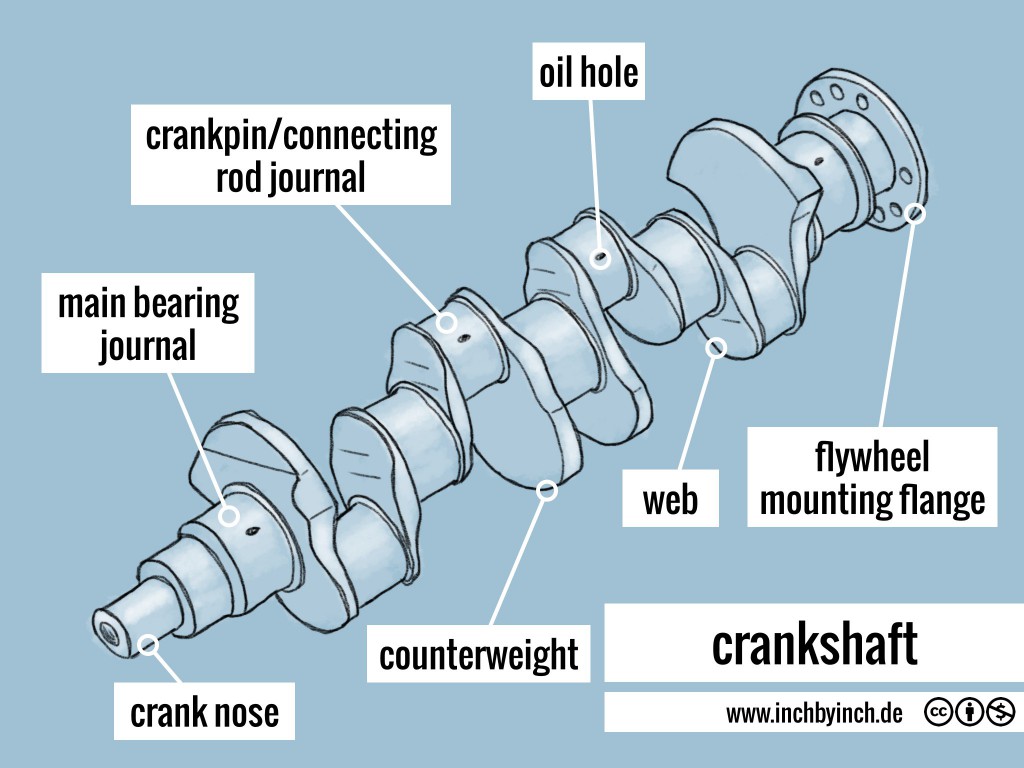

Crankshaft Main Journal - Web crankshaft wear and undersizing of journals. The whole crankshaft rotates around the axis of the main journal. Web the crankshaft is typically cast or forged of iron or steel. The main journal is a central part of the crankshaft with highly polished surface. This leads to wear of the crankpin and the journals. 83k views 2 years ago. All crankshaft journals are very hardened, rounded, and smooth. Web a typical crankshaft is made up of a series of main journals that support the crank in the block and a series of rod journals offset from the crank centerline that are affixed to the. There are several types of main journal bearings, which vary based on their design and materials. 8.2) fabricated from separate elements, which is mainly used for motorcycles.

How the crankshaft works All the details How a Car Works

Running smoothness is a universally important criterion for the design of crankshaft assemblies. A main bearing (center) of a napier deltic diesel locomotive engine (with.

Crankshaft Rod & Main Journal Measurement YouTube

Web the main bearing journals, or just main journals, are clamped into the engine block and it is around these journals that the engine rotates..

G23vtec crankshaft main journal oil bearing clearances check with

Web the parts of the crankshaft are given below: To do it right and not have to do it again in a month (or possibly.

Measuring Crankshaft Journals & How to use a Micrometer YouTube

Web the federal reserve's favored pce inflation gauge is due out early on friday. Web the crankshaft converts reciprocative motion to rotational motion. Web the.

Crankshaft Main Bearing Journal Measurements YouTube

Web the federal reserve's favored pce inflation gauge is due out early on friday. In addition to its main function of translating linear to rotary.

Crankshaft main journal and connecting rod journal measurements YouTube

The subscripts h, v and a represent hydrodynamic force, viscous friction force and asperity contact friction force,. The subscripts x and y represent the horizontal.

INCH Technical English crankshaft

The main journal is a central part of the crankshaft with highly polished surface. The whole crankshaft rotates around the axis of the main journal..

How to measure your crankshaft journals with a micrometer YouTube

Please see this answer for a better understanding of the different parts of a crankshaft and why it may be ground in the first place..

Grinding The Crankshaft Main Journals Changing The Wheel '68

Web the crankshaft is typically cast or forged of iron or steel. Today’s high output, close tolerance engines. Web creating the desired bearing clearance starts.

It Fits Into The Engine Block With Main Journal Bearings.

Web crankshaft wear and undersizing of journals. They support the crankshaft and allow it to rotate smoothly within the engine block. Today’s high output, close tolerance engines. The whole crankshaft rotates around the axis of the main journal.

Web The Crankshaft Is Typically Cast Or Forged Of Iron Or Steel.

Web a typical crankshaft is made up of a series of main journals that support the crank in the block and a series of rod journals offset from the crank centerline that are affixed to the. Web the parts of the crankshaft are given below: W and f are the static load (shaft weight) and dynamic force, respectively; Main size = main size).

A Main Bearing (Center) Of A Napier Deltic Diesel Locomotive Engine (With Its Crankshaft Removed) A Main Bearing Is A Bearing In A Piston Engine Which Holds The Crankshaft In Place And Allows It To Rotate Within The Engine Block.

All crankshaft journals are very hardened, rounded, and smooth. The subscripts h, v and a represent hydrodynamic force, viscous friction force and asperity contact friction force,. There are several types of main journal bearings, which vary based on their design and materials. Web creating the desired bearing clearance starts with accurately measuring the journal diameter.

83K Views 2 Years Ago.

Web number of main bearings. One of the best ways to assure. One end is connected with the flywheel flange and another end is connected with a pulley shaft. This leads to wear of the crankpin and the journals.